Vane Pump Installation Best Practices: A Technical Guide for Industrial Applications

Industry Background and Market Demand

Vane pumps are widely used in industrial applications due to their efficiency, reliability, and ability to handle low-viscosity fluids. Industries such as automotive, aerospace, chemical processing, and hydraulics rely on these pumps for lubrication, fuel transfer, and power transmission. The growing demand for energy-efficient fluid handling systems has increased the need for proper installation techniques to maximize performance and longevity.

This guide outlines best practices for vane pump installation, addressing key technical considerations, common challenges, and emerging trends.

---

Core Concepts and Key Technologies

A vane pump operates using a rotor with sliding vanes that create chambers to move fluid. The pump’s efficiency depends on:

- Radial or axial vane design – Determines pressure and flow characteristics.

- Vane material and sealing – Affects wear resistance and leakage control.

- Hydraulic balancing – Reduces internal friction and improves efficiency.

Proper installation ensures optimal alignment, lubrication, and pressure management, preventing premature failure.

---

Product Structure, Performance, and Manufacturing Considerations

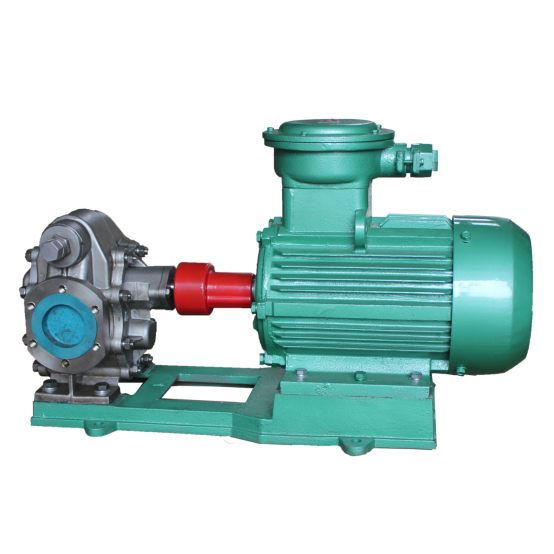

1. Pump Construction

- Housing – Typically made of cast iron, aluminum, or stainless steel for durability.

- Rotor and Vanes – Often constructed from hardened steel or composite materials to minimize wear.

- Shaft Seals – Lip seals or mechanical seals prevent fluid leakage.

2. Performance Factors

- Flow Rate and Pressure – Must match system requirements to avoid cavitation or excessive load.

- Viscosity Range – Vane pumps perform best with low to medium-viscosity fluids (e.g., hydraulic oils, solvents).

3. Manufacturing Precision

- Tight tolerances in rotor-vane clearance ensure efficient fluid displacement.

- Surface treatments (e.g., coatings, heat treatment) enhance wear resistance.

---

Key Factors Affecting Quality and Performance

1. Alignment and Mounting

- Misalignment causes shaft deflection, leading to seal failure and bearing wear.

- Use laser alignment tools for precision.

2. Lubrication and Priming

- Dry running damages vanes and seals. Pre-lubricate the pump before startup.

- Ensure proper fluid viscosity to maintain lubrication film.

3. Inlet Conditions

- Avoid suction-side restrictions to prevent cavitation.

- Maintain a flooded inlet or use a charge pump if needed.

4. System Cleanliness

- Contaminants (e.g., metal particles, dirt) accelerate wear. Install filtration (10–25 μm recommended).

---

Supplier Selection and Supply Chain Considerations

When sourcing vane pumps, evaluate suppliers based on:

- Certifications – ISO 9001, ASME, or industry-specific standards.

- Material Traceability – Ensures compliance with corrosion and wear requirements.

- Technical Support – Look for suppliers offering installation guidance and failure analysis.

Reliable suppliers provide detailed documentation, including performance curves and maintenance guidelines.

---

Common Challenges and Industry Pain Points

1. Vane Wear and Sticking

- Causes: Contaminated fluid, improper lubrication, or excessive pressure.

- Solution: Use wear-resistant materials and maintain filtration.

2. Seal Leakage

- Causes: Shaft misalignment, thermal expansion, or seal degradation.

- Solution: Ensure proper alignment and use compatible seal materials.

3. Noise and Vibration

- Causes: Cavitation, unbalanced rotor, or loose mounting.

- Solution: Check inlet conditions and secure mounting bolts.

---

Application Scenarios and Case Studies

1. Automotive Fuel Transfer

- Challenge: High-precision fuel delivery with minimal pulsation.

- Solution: Balanced vane pumps with corrosion-resistant materials ensure consistent flow.

2. Industrial Hydraulics

- Challenge: Handling high-pressure hydraulic fluids without leakage.

- Solution: Mechanically sealed vane pumps with reinforced housings.

3. Chemical Processing

- Challenge: Pumping aggressive solvents without material degradation.

- Solution: Stainless steel or PTFE-coated vanes resist chemical attack.

---

Current Trends and Future Developments

1. Smart Monitoring Systems

- IoT-enabled sensors track performance metrics (pressure, temperature, vibration) for predictive maintenance.

2. Advanced Materials

- Composite vanes and ceramic coatings improve durability in harsh environments.

3. Energy Efficiency

- Variable displacement vane pumps reduce power consumption in dynamic systems.

---

FAQ: Common Vane Pump Installation Questions

Q1: How often should vane pumps be inspected?

- A: Quarterly inspections are recommended for high-duty cycles; annually for light use.

Q2: Can vane pumps handle high-viscosity fluids?

- A: No, they are optimized for low to medium viscosity (typically < 500 cSt).

Q3: What causes excessive noise during operation?

- A: Cavitation, misalignment, or worn vanes are common culprits.

---

Conclusion

Proper vane pump installation is critical for performance, efficiency, and longevity. By addressing alignment, lubrication, and system design, engineers can minimize downtime and operational costs. As technology evolves, smart monitoring and advanced materials will further enhance reliability in industrial applications.

For optimal results, follow manufacturer guidelines and prioritize preventive maintenance to extend service life.

Phone

Phone

Comment

(0)